Thermal Transfer Overprinting (TTO) sets the industry standard for printing high-resolution variable data—including barcodes, text, and graphics—directly onto flexible packaging and labels.

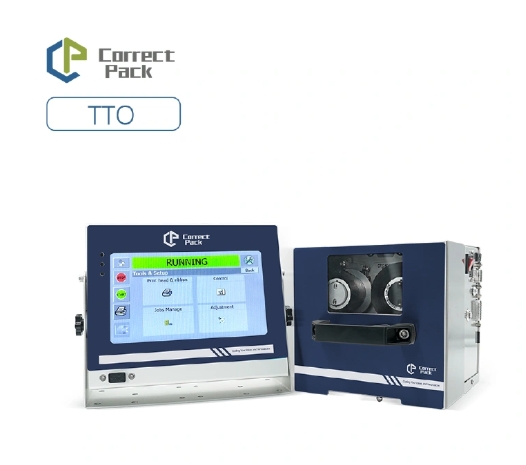

Economic & Intelligent Thermal Transfer Overprinter — High Quality, Cost-Effective, and an Easy Replacement for Ink Roller Printers.

SEND INQUIRY NOW

Thermal Transfer Overprinter represents the gold standard in high-resolution coding and marking for flexible packaging. Engineered for superior print quality and operational efficiency, our printers deliver crisp, scannable codes on various packaging materials while reducing operational costs and maintenance requirements.

How It Works

Thermal Transfer Overprinting operates through an intelligent digital process:

1. Ribbon Feeding: Precision-controlled ink ribbon advances between printhead and substrate

2.Thermal Activation: Printhead elements heat selectively, transferring ink from ribbon to material

3. Pixel-by-Pixel Printing: Digital technology creates high-resolution characters and graphics

4. Continuous Operation: Automatic ribbon advance ensures consistent print quality

5. Real-time Monitoring: Integrated sensors maintain optimal pressure and temperature

Key Features

Easy to Use

✩ One-button start

✩ Automatic height and parallel adjustment

Stable And Reliable

✩ Controlled by four motors

✩ Precise ribbon control

Quick Editing

✩ Editing on mobile and computer

✩ USB download Built-in print content.

Ribbon Efficiency

✩ Minimum ribbon spacing of 0.3mm

✩ Offset printing for radial savings

High Quality

✩ Rich printing content

✩ No need to create printing plates.

Smart Manufacturing

✩ Remote computer networking

✩ Easily monitor production status

Applications

Food & Beverage Packaging

➢Expiration dates on flexible pouches

➢Nutritional facts on snack bags

➢Lot codes on frozen food packaging

➢QR codes on beverage labels

Pharmaceutical & Medical

➢Batch numbers on blister packs

➢Sterilization dates on medical device packaging

➢UDI compliance markings

➢Manufacturing dates on specimen bags

Industrial & Consumer Goods

➢Variable data on shrink sleeves

➢Promotion codes on label stock

➢Sequential numbering on cable wraps

➢Security markings on high-value products

Frequently Asked Questions

Q: What's the typical ribbon life?

A: Ribbon yield depends on print coverage, but typically provides 50-80% more impressions than competitive systems due to our optimized saving technology.

Q: Can TTO print on curved surfaces?

A: While primarily for flexible materials, our systems can print on gently curved surfaces with proper fixturing.

Q: How often does the printhead need replacement?

A: With proper maintenance, printheads typically last 18-24 months in normal operation.

Q: What materials can TTO print on?

A: Excellent results on PET, PE, PP, PVC, coated papers, and most label stocks.

Q: Is special training required?

A: Basic operation requires under 1 hour. Advanced maintenance training is recommended for technical staff.

Q: What's the ROI timeframe?

A: Most customers achieve full ROI within 6-12 months through reduced waste, lower consumable costs, and increased efficiency.

Technical Parameters

Item Type/Model | E72(24mm) | E73(32mm) |

Printing Modes | Intermittent & continuous modes in the same machine | |

Directional Options | Left and right directions selectable | |

200DPI | 300DPI | |

Intermittent Mode Maximum Print Area | 24mm X 45mm | 32mm X 55mm |

Continuous Mode Maximum Print Area | 24mm X 100mm | 32mm X 100mm |

Intermittent Printing Speed | 50~300mm/s | |

Continuous Printing Speed | 30~600mm/s | |

Maximum Printing Frequency | 220 times/minute | |

Ribbon Length | 400m | 600m |

Ribbon Width | 25mm | 33mm |

| Printing Content | Date, future date, time, counter, shift barcode, QR code, image, text | |

Inputs | Print signal, encoder signal | |

Outputs | Fault status output (relay signal output). | |

Printer Dimensions (L x W x H in mm) | 164X158X150 | |

Printer Weight | 5kg | 5.5kg |

| Power | 110-220V AC, 50/60HZ, 120W | |

| Environmental | Temperature: 5-40°C. Humidity: 10% to 90%, non-condensing | |

Economic Intelligent Thermal Transfer Overprinter High Quality and Cost-Effective Makes Your Work More Efficient, Easily Replacing Ink Roller Printers.

Science and technology oriented, continuous improvement, Correct Pack always committed to providing customers with valuable products and satisfy services