The fiber laser marking machine series are designed to meet the needs of manufacturers who use robust, high density materials on medium-speed or high-speed production lines. For example, factories of the beverage, wire, cable, pipe and pharmaceutical industries urgently need fiber laser marking machines to meet their increasing production volume and provide high-quality markings.

SEND INQUIRY NOW

Uptime advantage

The durable laser source, minimal maintenance requirements and low consumables help reduce unplanned and planned downtime and ensure minimal manual intervention during production. Practical and reliable operating software further maximizes the utilization rate of the laser coding machine, and quickly implements installation settings and production line conversion steps.

Encoding quality assurance

The advanced fiber laser marking machine controller can reduce the operator's input in the coding and marking process, to avoid coding errors. You can mark the right codes on the proper position of the corresponding product time after time.

Built-in productivity

Achieve top speeds with serialization data and complex codes and faster data processing capabilities, coupled with a large printing area, can increase throughput and performance, then make the production line run normally.

Easy to use

Provide a variety of standard configuration options and accessories, which ensures the laser coding machine can be used in conjunction with your production workflow. Coupled with easy operation, your team can focus on

production without much user intervention and equipment maintenance.

A fiber laser printer (more accurately called a fiber laser marking/engraving machine) is a specialized industrial tool used to permanently mark or engrave surfaces using a fiber laser source. Unlike traditional printers (which use ink or toner), fiber laser printers use a high-intensity laser beam to alter materials at a microscopic level, creating precise, durable marks without physical contact.

Key Features and How It Works

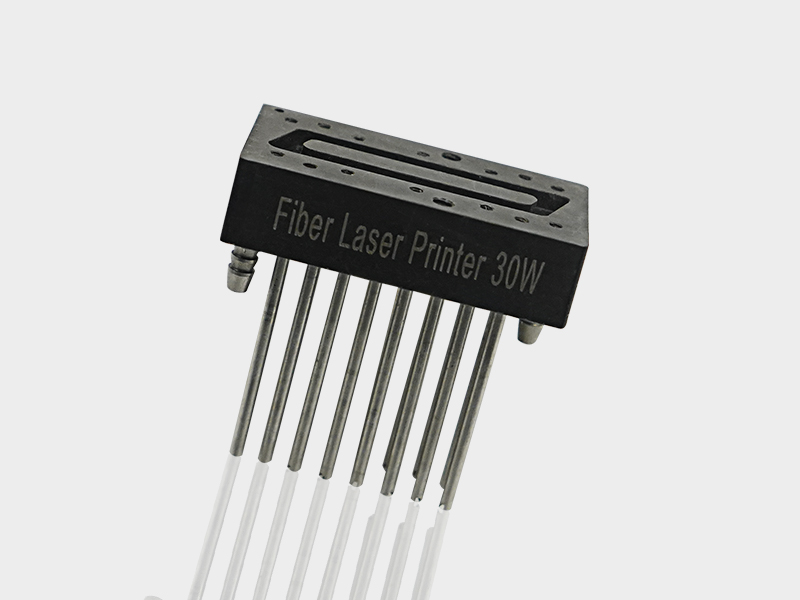

Fiber Laser Source:

Generates a laser beam using optical fibers doped with rare-earth elements (e.g., ytterbium).

Wavelength: 1064 nm (ideal for metals and some plastics).

Non-Contact Process:

The laser beam interacts with the material’s surface, causing changes like:

Annealing: Heat-induced color changes (common on metals).

Ablation: Removing material to create engravings.

Foaming: Creating contrast on plastics.

High Precision:

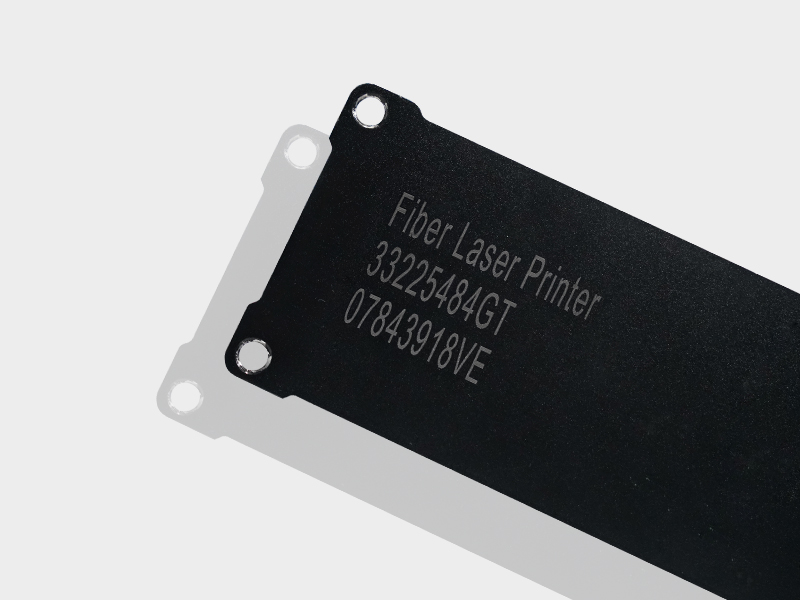

Can mark tiny details (e.g., 0.01mm text, QR codes, micro-serial numbers).

Speed and Efficiency:

Marks surfaces quickly, making it ideal for high-volume industrial production.

Advantages

Permanent Marks: Resistant to heat, abrasion, and chemicals.

Material Versatility: Works on metals (steel, aluminum, titanium), plastics, ceramics, and some composites.

Low Maintenance: Fiber lasers have long lifespans (often 100,000+ hours).

Energy-Efficient: Uses less power than CO₂ lasers.

No Consumables: Requires no ink, solvents, or chemicals.

Common Applications

Industrial Part Marking: Serial numbers, barcodes, or logos on automotive/aerospace components.

Electronics: Labeling circuit boards (PCBs) or microchips.

Medical Devices: Engraving surgical tools or implants for traceability.

Jewelry: Personalized engravings on rings, watches, or bracelets.

Tool Identification: Permanent marks on molds, dies, or machinery.

Why Choose a Fiber Laser Printer?

It’s ideal for industries needing high-precision, permanent marks on metals or hard materials. While not used for paper printing, it excels in manufacturing, electronics, jewelry, and medical sectors where durability and precision are critical.

Item Typ / Model | CP6020F |

Machine material | Aluminum structures+Stainless Steel |

Laser | Fiber laser generator |

Output power | 20W/30W/50W |

Laser wavelength | 1064nm |

Lens | High precision 2D scanning system |

Jump speed | ≤10000mm/s / ≤12000mm/s |

Main control system | Highly-integrated mainboard, with embedded 10.1 inch controller |

Cooling system | Air cooled |

Focus zoom lens | 166mm double red light focusing |

Marking scale type | Raster fonts, vector fonts are available |

Minimum marking line width | 0.1mm |

Minimum character height | 0.15mm |

Working area | 110X110mm |

Positioning | Red light posiƟ oning and double red light focusing |

Lines of marking | No limited in working area |

Speed | 0~200m/min |

Power | 110VA/220VA |

Power consumpƟ on | 600W |

Bottle Caps

Cans

Carton

HDPE Light Bulb

Metal Fittings

Metal Fittings

PE Material Box

Pen

Pet Tag

Plastic Accessory

Plastic Accessory

Plastic Accessory

Plastic Parts

Plastic

Rubber Parts Cover

Scissors

Snack Bag

Stainless Steel Label Strip

![]() Fiber Laser Series Brochure (6020F.6030F.6050F)

Fiber Laser Series Brochure (6020F.6030F.6050F)

Fiber Laser Marking Machine suitable for Gold, Silver, Diamond,Sanitary Equipments, Foods Packing, Tobacco Label, Beer label,Drink Label, Medicine Packing, Medical Equipments, Glasses andClock, Auto Parts,Plastic& Paper Materials,The Electron, Hardwarewhich with high request for depth, smooth, accuracy such as horologe, Mould, bitmap marking etc.

Science and technology oriented, continuous improvement, Correct Pack always committed to providing customers with valuable products and satisfy services